The Ultimate OEM Digital Timers Guide for 2026: Selection, Customization, and Integration

This definitive guide for 2026 navigates the complex landscape of OEM digital timers. Designed for engineers and procurement leaders, it covers essential selection criteria, customization strategies, and integration with modern industrial protocols like Modbus and IoT. We explore the shift from standard components to bespoke solutions, referencing key standards such as IEC 61812-1 and UL 508, to help manufacturers secure a competitive edge.

- Introduction to OEM Digital Timers

- The Core Advantages of Digital Timers for OEMs

- Precision and Reliability

- Programmability and Flexibility

- Integration Capabilities

- Energy Efficiency and Durability

- Key Considerations for OEMs When Selecting Digital Timers

- Technical Specifications & Performance

- Customization Capabilities

- Quality and Reliability Assurance

- Supply Chain & Logistics

- Types of Digital Timers Ideal for OEM Applications

- On-Delay & Off-Delay Timers

- Cyclic and Multifunction Timers

- Astronomical and Smart Timers

- Applications of OEM Digital Timers Across Industries

- Industrial Automation

- Medical Devices

- Energy Management

- How to Partner with the Right OEM Digital Timer Manufacturer

- Assessing Capabilities

- Pricing and Long-Term Value

- Future Trends in OEM Digital Timer Technology

- IoT and Cloud Connectivity

- AI and Predictive Maintenance

- Miniaturization

- Conclusion: Empowering Innovation with Strategic OEM Digital Timer Choices

- Frequently Asked Questions

- What does "OEM" mean in the context of digital timers?

- How do OEM digital timers differ from off-the-shelf consumer digital timers?

- What level of customization can an OEM expect?

- What are the critical certifications for OEM digital timers?

- How does an OEM ensure long-term supply chain stability?

- Can OEM digital timers be integrated with IoT platforms?

- What is the typical lead time for custom OEM digital timer orders?

- What are the cost implications of custom versus standard timers?

- References

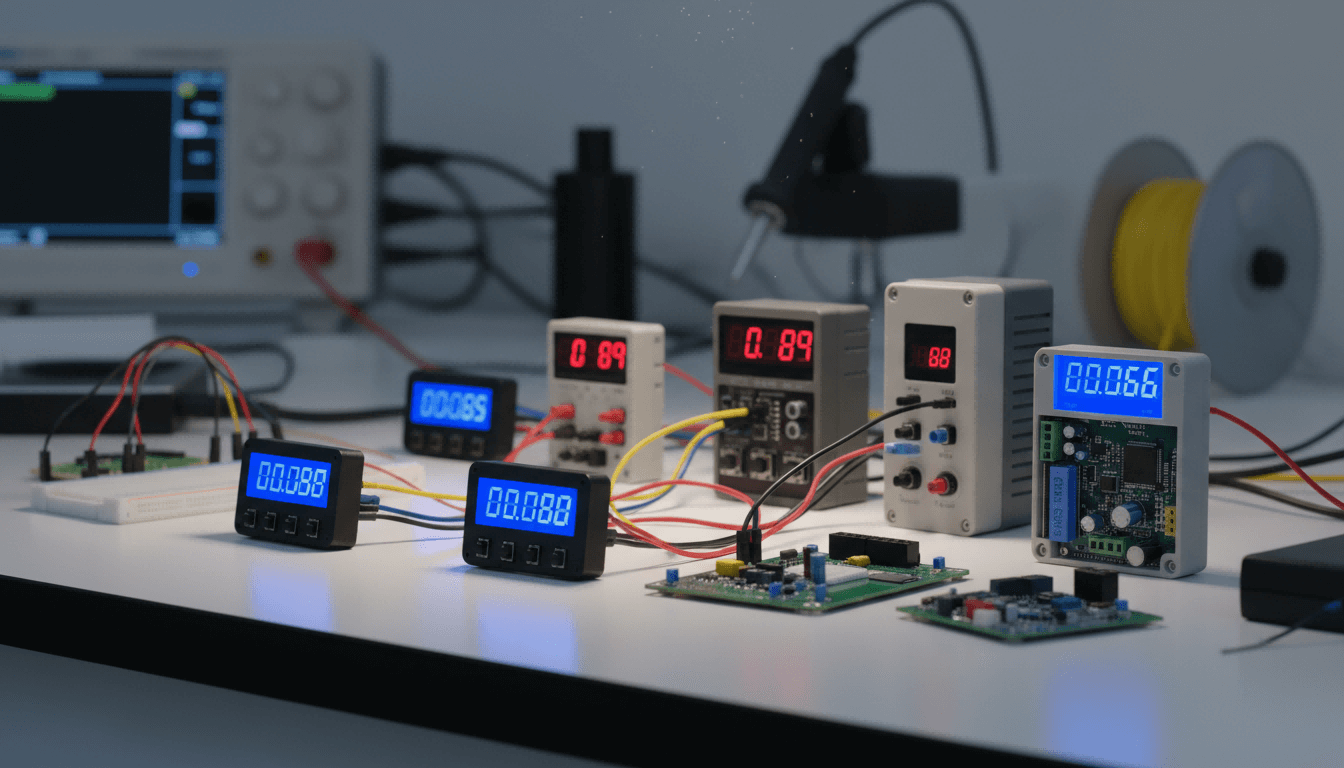

Introduction to OEM Digital Timers

In the rapidly evolving landscape of industrial automation and consumer electronics, the timer is rarely just a simple clock; it is the heartbeat of operational logic. Industrial digital timer OEM partnerships have moved beyond simple component purchasing to become strategic collaborations that define product reliability and functionality. Original Equipment Manufacturers (OEMs) today face increasing pressure to deliver systems that are not only precise but also intelligent and interconnected.

An OEM digital timer is a timing device manufactured specifically to be integrated into a larger system—be it a medical sterilization unit, an industrial conveyor, or a smart building control panel. Unlike off-the-shelf commercial timers, these devices are engineered for rigorous specifications, often requiring custom digital timer solutions that fit unique form factors or execute complex, proprietary logic. As manufacturing enters the Industry 4.0 era, the transition from mechanical to advanced digital timing solutions is no longer optional; it is a critical requirement for maintaining competitive advantage.

The Core Advantages of Digital Timers for OEMs

For an OEM, the choice between a mechanical and a digital timer often dictates the lifespan and perceived quality of the final product. Digital timers offer a suite of advantages that align with modern engineering demands.

Precision and Reliability

Mechanical timers rely on gears and springs, which are subject to physical wear and environmental drift. In contrast, digital timers utilize quartz crystal oscillators or microcontrollers. According to data compared by industry experts, while mechanical timers may drift significantly (up to ±10%), digital relays can achieve accuracy within ±0.1% or better, down to the millisecond. This level of precision is non-negotiable in applications like chemical dosing or high-speed packaging.

Programmability and Flexibility

Modern programmable timer manufacturing allows for a single hardware unit to perform multiple functions. Through firmware adjustments, an OEM can configure a timer for delay-on-make, delay-on-break, or interval operations without changing the physical component. This flexibility reduces inventory complexity and allows for rapid prototyping of new product variants.

Integration Capabilities

The true power of digital timers lies in their ability to communicate. Unlike their isolated mechanical predecessors, digital timers can integrate with broader control networks using protocols such as I2C, SPI, or Modbus. This facilitates digital timer integration for OEMs, allowing the timer to report status, accept remote setpoints, and trigger alarms within a central PLC or SCADA system.

Energy Efficiency and Durability

Digital solid-state designs eliminate moving parts, significantly extending the Mean Time Between Failures (MTBF). Furthermore, they often feature low-power standby modes, a crucial factor for battery-operated or energy-conscious designs mandated by newer environmental regulations.

Key Considerations for OEMs When Selecting Digital Timers

Selecting the right timer involves balancing technical constraints with commercial realities. This OEM timer sourcing guide section outlines the critical evaluation points.

Technical Specifications & Performance

Engineers must define the required timing range (milliseconds to days), voltage inputs (12VDC to 240VAC), and output ratings. However, environmental factors are equally vital. For instance, bulk digital timers supply orders for outdoor agricultural equipment must meet higher IP ratings (e.g., IP65 or IP67) compared to those intended for climate-controlled server rooms.

Customization Capabilities

One of the primary reasons to engage an OEM partner is customization. This goes beyond branding. It involves:

· Hardware: Custom PCB shapes to fit tight enclosures.

· Firmware: Pre-programmed logic sequences unique to the OEM's machine.

· Interface: Custom LCD segments or specific LED indicators.

Quality and Reliability Assurance

Adherence to international standards is the baseline for trust. UL 508 (Industrial Control Equipment) and IEC 61812-1 (Time relays for industrial and residential use) are the gold standards. As noted in technical compliance guides, IEC 61812-1 specifically defines the tests and performance requirements for time relays in industrial environments, ensuring they withstand electromagnetic interference (EMI) and vibration.

Supply Chain & Logistics

In a post-pandemic world, supply chain stability is paramount. When negotiating bulk digital timers supply, OEMs must evaluate the supplier's ability to buffer stock and manage component obsolescence. Dual-sourcing critical ICs or having a "white label" agreement with a manufacturer who has global distribution centers can mitigate long lead times.

Types of Digital Timers Ideal for OEM Applications

Understanding the specific classification of timers ensures the correct component is specified for the application.

On-Delay & Off-Delay Timers

These are the workhorses of automation. On-delay timers wait for a set time after power is applied before switching, protecting motors from short-cycling. Off-delay timers keep a load running for a set time after the signal is removed, commonly used in cooling fans.

Cyclic and Multifunction Timers

Cyclic timers (or flashers) are essential for repetitive tasks like lubrication intervals or warning lights. Multifunction timers offer the highest versatility, allowing the end-user or the OEM to select the mode via dip switches or software, streamlining programmable timer manufacturing logistics.

Astronomical and Smart Timers

Used increasingly in building management, these timers calculate sunrise and sunset times based on geolocation, eliminating the need for photocells. These are often the entry point for IoT digital timers for manufacturing smart lighting systems.

Applications of OEM Digital Timers Across Industries

Industrial Automation

In factory settings, digital timers coordinate conveyor belts, robotic arms, and safety curtains. The integration of protocols like Modbus allows these timers to provide real-time data to the factory floor's central brain, enhancing overall Overall Equipment Effectiveness (OEE).

Medical Devices

Precision is a matter of life and death in medical OEMs. Digital timers control UV sterilization cycles, centrifuge operation times, and precise dosing mechanisms, where certification bodies demand rigorous validation of timing accuracy.

Energy Management

Smart grids utilize digital timers for load shedding—turning off non-essential equipment during peak demand hours. This application drives the demand for white label digital timers that utility companies can brand and distribute to their commercial customers.

How to Partner with the Right OEM Digital Timer Manufacturer

Choosing a manufacturer is as critical as choosing the component itself. The distinction between an OEM (Original Equipment Manufacturer) and an ODM (Original Design Manufacturer) is vital here. As defined by industry resources, an OEM typically builds to your specific design, whereas an ODM provides a pre-designed product that you can rebrand.

Assessing Capabilities

Look for partners with in-house R&D that can handle digital timer integration for OEMs. Can they modify the firmware to speak your proprietary protocol? Do they have their own EMC testing labs to ensure compliance with IEC 61812-1 before external certification?

Pricing and Long-Term Value

While unit cost is important, the Total Cost of Ownership (TCO) matters more. A cheaper timer that fails early or requires complex manual programming on the assembly line costs more in the long run. Negotiate volume discounts but also prioritize warranty terms and technical support SLAs.

Future Trends in OEM Digital Timer Technology

IoT and Cloud Connectivity

The future is connected. IoT digital timers for manufacturing are now capable of connecting directly to Wi-Fi or LoRaWAN networks. This allows for remote monitoring and "Over-the-Air" (OTA) firmware updates, meaning an OEM can upgrade a machine's logic without sending a technician to the site.

AI and Predictive Maintenance

Emerging trends suggest that by 2026, timers will not just count seconds; they will analyze them. Integrated AI can monitor current draw during the timing cycle to predict mechanical wear in the connected load, alerting the system before a failure occurs. This aligns with the broader push for predictive maintenance in industrial IoT.

Miniaturization

As electronics shrink, the demand for 1/16 DIN or even smaller, board-level timing modules increases. This pushes manufacturers to innovate with high-density interconnects and chip-scale packaging.

Conclusion: Empowering Innovation with Strategic OEM Digital Timer Choices

For the modern OEM, a digital timer is a strategic asset. Whether you are sourcing white label digital timers to expand your catalog or engineering a custom digital timer solution for a breakthrough medical device, the principles of selection remain the same: prioritize precision, demand compliance, and plan for connectivity. By leveraging the standards and technologies outlined in this guide, OEMs can build products that stand the test of time—literally and figuratively.

Frequently Asked Questions

What does "OEM" mean in the context of digital timers?

OEM refers to Original Equipment Manufacturers. In this context, it entails a B2B relationship where a manufacturer produces digital timers specifically to be integrated into another company's final product, often with custom specifications or branding.

How do OEM digital timers differ from off-the-shelf consumer digital timers?

OEM timers are built for industrial-grade reliability, higher precision (often ±0.1%), and harsh environments. They support integration protocols like Modbus and offer customization options for hardware and firmware that consumer models lack.

What level of customization can an OEM expect?

Customization ranges from cosmetic changes (branding, housing color) to deep technical modifications, including custom timing logic, specific voltage inputs, specialized connectors, and integration of proprietary communication protocols.

What are the critical certifications for OEM digital timers?

The most critical certifications are UL 508 (for safety in industrial control equipment) and IEC 61812-1 (specific performance and safety requirements for time relays). RoHS compliance is also mandatory for environmental standards in many regions.

How does an OEM ensure long-term supply chain stability?

OEMs should look for suppliers with diverse manufacturing locations, establish long-term supply agreements, and select components that are not near their End-of-Life (EOL). Verifying the supplier's financial health and stock buffering capabilities is also crucial.

Can OEM digital timers be integrated with IoT platforms?

Yes. Modern OEM timers can feature communication ports (RS-485, Ethernet) or wireless modules (Wi-Fi, Bluetooth) to send data to IoT gateways, enabling remote monitoring and control via cloud platforms.

What is the typical lead time for custom OEM digital timer orders?

Lead times vary: standard "white label" products might take 4-6 weeks, while fully custom hardware solutions requiring new tooling and certification can take 12-24 weeks or more.

What are the cost implications of custom versus standard timers?

Custom timers generally carry Non-Recurring Engineering (NRE) fees upfront and may have a higher unit cost at low volumes. However, at high volumes, they can reduce total system costs by eliminating the need for external converters or extra components.

References

· Process Solutions: Understanding UL 508A Industrial Control Panel Standards

· Wevolver: OEM vs ODM Manufacturing: A Comprehensive Technical Guide for Engineers

Contacts

Sofia

WhatsApp/Phone

All

Do you offer OEM & ODM clock services?

Yes, we provide both OEM & ODM solutions, allowing clients to customize clock design, materials, packaging, and branding.

What types of clocks can you manufacture?

We manufacture a wide range of clocks, including wall clocks, desk clocks, digital clocks, and smart clocks.

Can I customize the clock design and logo?

Absolutely. We offer customization for clock appearance, structure, materials, and logo printing to perfectly match your brand.

What is the minimum order quantity (MOQ)?

Our standard MOQ varies depending on the model, usually starting from 200–500 pieces. Custom designs may require different quantities.

How do you ensure product quality?

All clocks undergo strict quality control, including time accuracy tests, durability checks, and packaging inspections before shipment.

Interested in this article?

Let’s talk.

Need specifications, pricing, or customization options? We’ll provide everything you need.

By clicking “Submit,” you agree to share your information with our authorized team to process your request.

Your data will only be used for necessary communication and support.

Youben life

Youben life

Youben life

Youben life